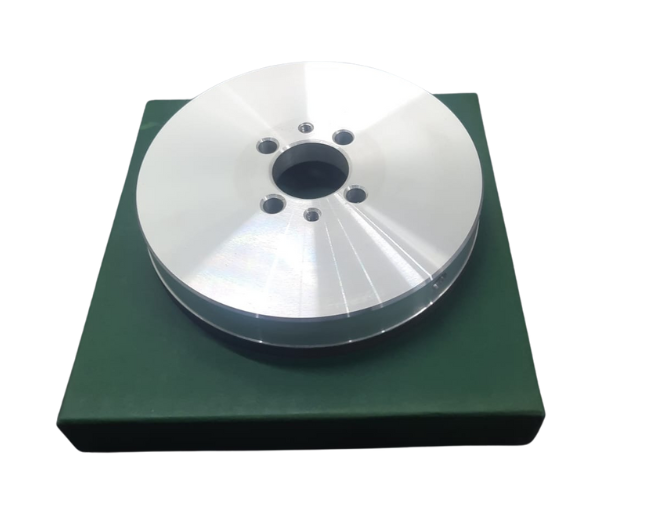

CBN Grinding Wheel for Amada TOGU & Wilson Tool Grinders

Upgrade your tool maintenance with high-performance CBN (Cubic Boron Nitride) grinding wheels designed for Amada TOGU III and Wilson Tool grinders. These wheels deliver accurate, stable and repeatable regrinding for turret punch press tooling. They help maintain sharp edges, improve punching quality and extend the life of punches and dies. Built for hardened tool steels, CBN wheels offer excellent thermal control and steady performance during wet grinding.

Key Features

- CBN Abrasive Technology – Superior hardness and heat resistance for precise regrinding of hardened tooling.

- Perfect Fit for TOGU & Wilson Grinders – Fully compatible with Amada TOGU III and Wilson Tool sharpening systems.

- CBN abrasive provides high hardness and thermal stability for accurate sharpening.

- Fully compatible with Amada TOGU III and Wilson Tool grinders.

- Produces smooth, accurate finishes with minimal burrs.

- Supports wet grinding for lower heat and better edge protection.

- Long-lasting bond reduces wheel wear and maintenance costs.

Applications

- Regrinding punches and dies for turret punch presses:Helps restore edge sharpness and geometry, ensuring clean and accurate punching across production runs.

- Fabrication shops using Amada or Wilson tooling: Ideal for operations that depend on steady punch performance and consistent hole quality in sheet metal work.

- Tool rooms focused on precision and repeatability: Supports controlled sharpening cycles, improved surface finish and reliable part output.

- Shops using servo-controlled wet grinding systems: Works smoothly with wet grinding setups by managing temperature and reducing the risk of tool softening.

- Maintenance teams responsible for tool life extension: Helps extend service life of punches and dies, reducing replacement frequency and lowering running costs.

- Surface Finish Requirements: Delicate materials need tooling that avoids scratches and marks. Coated or radius tools help maintain a clean finish. Selecting the right surface-friendly tools reduces post-processing work.

How CBN Wheels Improve Tool Life

CBN grains cut with reduced friction, keeping heat under control and preventing damage to the punch or die tip. This protects hardness, maintains geometry and keeps tools sharp for more cycles.

Performance Compared to Conventional Wheels

Conventional wheels wear faster and generate more heat. CBN wheels hold shape, cut consistently and require less dressing, improving accuracy and reducing burrs.

Why Choose Remitek CBN Grinding Wheels

Remitek wheels are balanced for smooth operation and consistent cutting. They match the requirements of TOGU and Wilson grinders for simple setup and reliable use. Built with a strong bond and high-quality CBN grains, they deliver long service life and clean results. With dependable support and quick availability, Remitek is a strong choice for precise tool maintenance.